Solar Protein

Feeding the world’s growing population and reducing the environmental impact of food production. These are two major challenges for mankind and they drive the search for innovative methods of food production, requiring minimal input of fossil fuels. Our focus on microbial protein is one of the solutions.

NATURAL FOOD

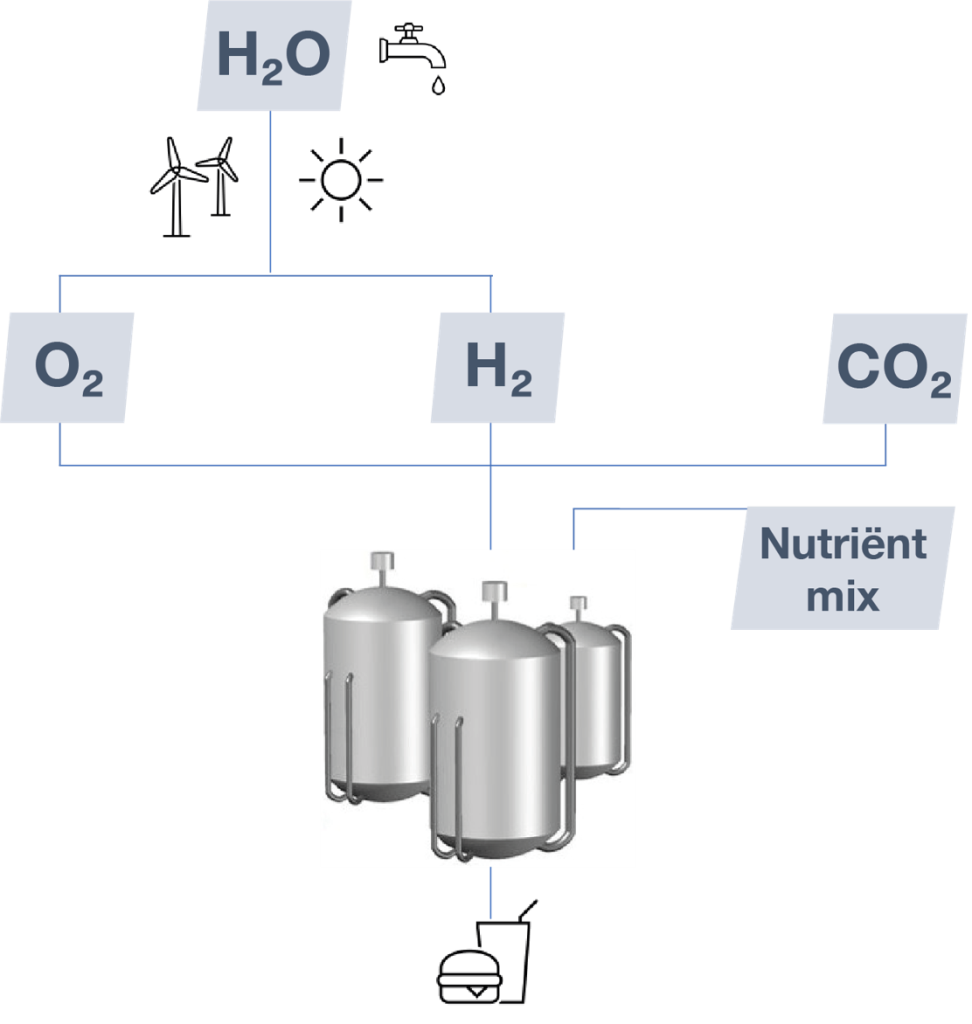

Proteins for human consumption typically originate from plants, fish or terrestrial animal sources. A relatively new approach is based on microbial proteins. As main sources, we focus on autotrophic bacteria which grow on (green) hydrogen, oxygen, CO2 and reactive nitrogen. Instead of the latter, even nitrogen from the air can be utilized by the autotrophic bacteria. The key advantages of these microbial proteins compared to conventional proteins include (1) substantially lower footprint and water consumption, (2) fewer emissions (pesticides, nutrients, greenhouse gases) and – last but not least – (3) an animal-friendly system.

The concept is based on the use of green hydrogen, which is produced by splitting water into hydrogen and oxygen through the electrolysis of water. The electricity required is generated from renewable sources such as wind and solar power. Hence we use the term Solar Protein. The composition of the Solar Protein is more or less comparable to fish protein. See the table below.

Solar Protein is suitable for food applications if all source compounds have virgin quality. Alternatively, source compounds for certain feed proteins can be recovered from residuals streams, e.g. CO2 from off-gas and ammonia from liquid streams. An example is the Power-to-Protein concept (www.powertoprotein.eu).

| Unit | Plant protein | Animal protein | Solar Protein | Source | |

| Footprint | m2/kg | 5 | 20 | <1 | 1 |

| Water consumption | m3/kg | 15 | 30 | <1 | 1 |

| N uptake efficiency | % | 26 | 7 | 80 | 2 |

| Greenhouse gas emission | kg CO2e/kg | 100 | 300 | <10 | 1 |

(1) World Resource Institute, 2016 (animal protein: corn and poultry); (2) Pikaar et al, Environm. Sci. Techn., 2017

OUR TEAM

The Solar Protein team is a collaboration between Allied Waters, Avecom (www.avecom.be) and KWR (www.kwrwater.nl). Following multi-year research and development on lab and pilot scale, the process is now ready for further upscaling.

Allied Waters, driving the circular economy.