From sugar beets to tomatoes: sustainable water supply agro- and foodcluster Nieuw Prinsenland

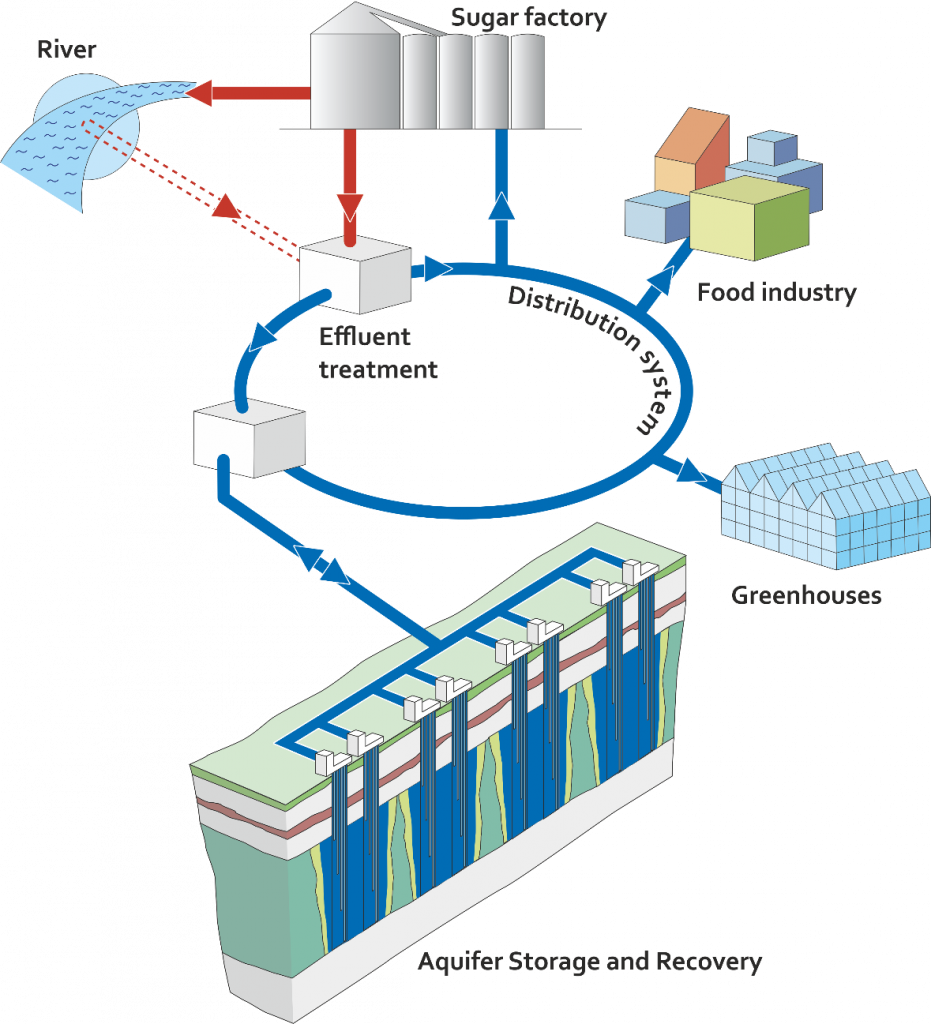

The continuous availability of high-quality freshwater is vital for the greenhouse horticulture industry. However, this was not readily available at the Agro- and Foodcluster Nieuw Prinsenland in Dinteloord (The Netherlands). Although the annual water demand at the greenhouses in the area could be largely satisfied through the collection of rainwater and its storage in surface basins, serious seasonal shortages would result during periods of drought. Surface water could not provide a water source, as it is scarce and of a poor quality in the area. The groundwater is brackish and not naturally recharged.

DOWNLOAD THIS PAGE AS FACTSHEET (.PDF) >>

Challenge: Availability of high-quality freshwater

Effluent water from a neighbouring sugar factory provided an alternative freshwater source. The factory processes sugar beets into sugar from September until the end of January. This operation releases huge quantities of freshwater. Through additional treatment based on ultrafiltration and reverse osmosis, this water can be transformed into high-quality, demineralized water for greenhouse irrigation. But one problem remained: where can the water be stored during periods of surplus for later use in periods of drought? Storage in surface basins has several drawbacks, including its high costs, extensive spatial needs, and possible deterioration of the water quality during such ‘open storage’: warming, algal growth, atmospheric deposition, or even sabotage.

Solution: subsurface storage as essential link

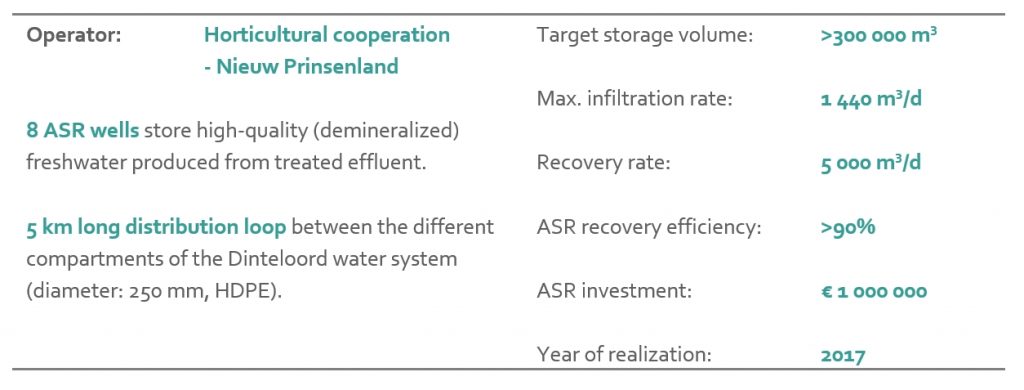

The subsurface provides the space to balance water supply and demand over time. Allied Waters SALutions has made aquifer storage and recovery (ASR) suitable for application in brackish groundwater, fully integrated in the daily operation of greenhouse owners. This inspired TOM to further explore whether and how ASR could be used for subsurface storage of the treated effluent in Nieuw Prinsenland. The combination of ASR and water reuse proved logical and economically attractive, with costs for aquifer storage around 0.5 euro/m3 of water supplied and a spatial footprint of virtually nil. For comparison: the projected costs of a large aboveground reservoir would be almost 3.0 euro/m3 supplied. A full-scale ASR reuse system (8 wells) has been installed in 2017 and is supplying greenhouse farmers, the neighbouring sugar factory, and potentially bio-based industries with an additional 300,000 m3 of freshwater per year.

FIGURE 1: OUTLINE OF THE DINTELOORD WATER SYSTEM

Characteristics

FIGURE 2: IMPRESSION OF THE ASR WELL FIELD IN AN ECOLOGICAL CORRIDOR IN THE GREENHOUSE AREA

Project video

Services provided by Allied Waters

- Identification of suitable locations for the ASR well field, taking into account the soil structure, groundwater quality, and surrounding infrastructure.

- Set-up of the preliminary design of the ASR scheme.

- Analysis of the hydrological impact on the surroundings; permitting.

- Design of a fully automated installation with Codema Systems Group, allowing for automated injection of treated effluent through the ASR wells and automatic supply of recovered water when demanded.

- Small-scale ASR pilot at the most suitable location, involving one ASR well and the storage of almost 10,000 m3 of treated effluent.

- Evaluation of the ASR test cycle (hydrological effects, water quality developments, compliance) and final design of the whole ASR well-field.

- Operation and evaluation of the first operational ASR cycle and supervision on the expansion of the ASR well field to its operational capacity of 300,000 m3/yr.

- Set up of a detailed water balance of the Dinteloord greenhouse area, based upon acquiring detailed operation data of the water users. Assessment of the required target storage volume of the ASR scheme and its operational constraints to effectively supplement the horticulturists’ rainwater basins and the potential of using basin overflow for ASR in the future.

- Daily liaison with TOM; daily operation of ASR well field (automated); compliance.

Clients

- Horticultural development company (TOM) Brabant: www.tombrabant.nl

- Coöperatieve Vereniging Glastuinbouw Nieuw Prinsenland u.a.